Air-powered logic circuits, also known as pneumatic logic circuits, are innovative systems that use compressed air instead of electricity to perform computational and control functions. As reported by the University of California, Irvine, these circuits are gaining importance in various fields, from bioengineering to soft robotics, offering unique advantages in environments where traditional electronic systems may be impractical or hazardous.

Operation of Air Logic Circuits

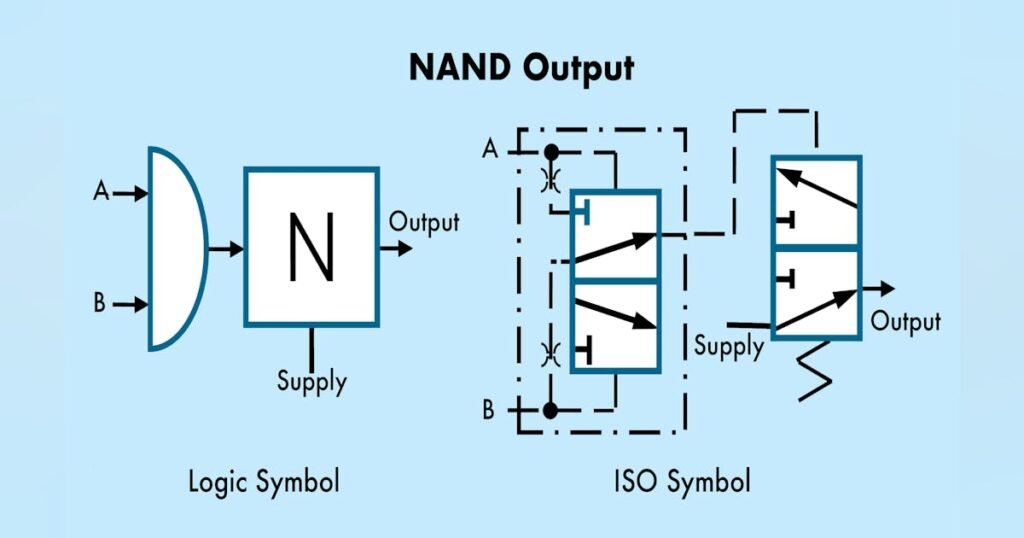

Air logic circuits utilize miniaturized 3- and 4-way air valves to perform operations analogous to electronic components. These valves function as switches, relays, and counters, using variations in air pressure to encode binary data – typically with vacuum pressure representing “1” and atmospheric pressure representing “0”. The circuits employ basic logic elements such as AND, OR, and NOT gates, which can be combined to create more complex functions. For example, an AND element requires simultaneous input signals to produce an output, while an OR element generates an output with a signal at either input port. This pneumatic approach allows for the creation of sophisticated control systems without relying on electricity, making it suitable for environments where electronic systems may pose risks.

Applications and Advantages

Pneumatic logic circuits find applications in diverse fields, offering unique advantages over electronic systems. In wet or dusty environments, these air-powered controls excel due to their resistance to moisture and particulates, making them ideal for industrial settings. They are particularly valuable in explosive atmospheres, as compressed air cannot ignite flammable gases or vapors. The technology has gained traction in microfluidics, with researchers at the University of California, Irvine developing a pneumatic computer for lab-on-a-chip devices. This innovation eliminates the need for bulky external apparatus, potentially revolutionizing applications such as epidemiological testing, environmental monitoring, and food safety. Additionally, air logic controls are preferred in facilities where only one utility service is available, simplifying maintenance by requiring expertise from a single labor trade.

Challenges in Pneumatic Logic

While offering unique advantages, pneumatic logic circuits face several challenges. Response times can be noticeably slower than electronic counterparts, especially with control lines longer than 10 to 15 feet, due to the time required to fill and exhaust air.Maintenance and troubleshooting pose difficulties, as many technicians lack familiarity with air logic schematics and operation. Additionally, these systems require a high-quality, filtered air supply to ensure consistent performance and longevity. The need for specialized knowledge in both pneumatics and logic design can limit widespread adoption and development of more complex air-powered computing systems.

Recent Pneumatic Innovations

Recent advancements have pushed the boundaries of pneumatic computing, with researchers developing sophisticated air-powered systems capable of encoding and decoding data on lab-on-a-chip devices. In June 2023, a team from the University of California, Irvine and California State University, Long Beach unveiled a breakthrough pneumatic computer that eliminates the need for external electronic interfaces. This innovation utilizes a 0.25-millimeter-thick silicone sheet sandwiched between glass panes with etched channels, mimicking electronic transistors through pressure variations.Such developments hold promise for applications in soft robotics, medical prosthetics, and microfluidic systems, potentially revolutionizing fields like epidemiological testing and environmental monitoring.

Source: Perplexity